Inspirating Info About Does Arduino Use PLC

Arduino and PLCs

1. Understanding the Playing Field

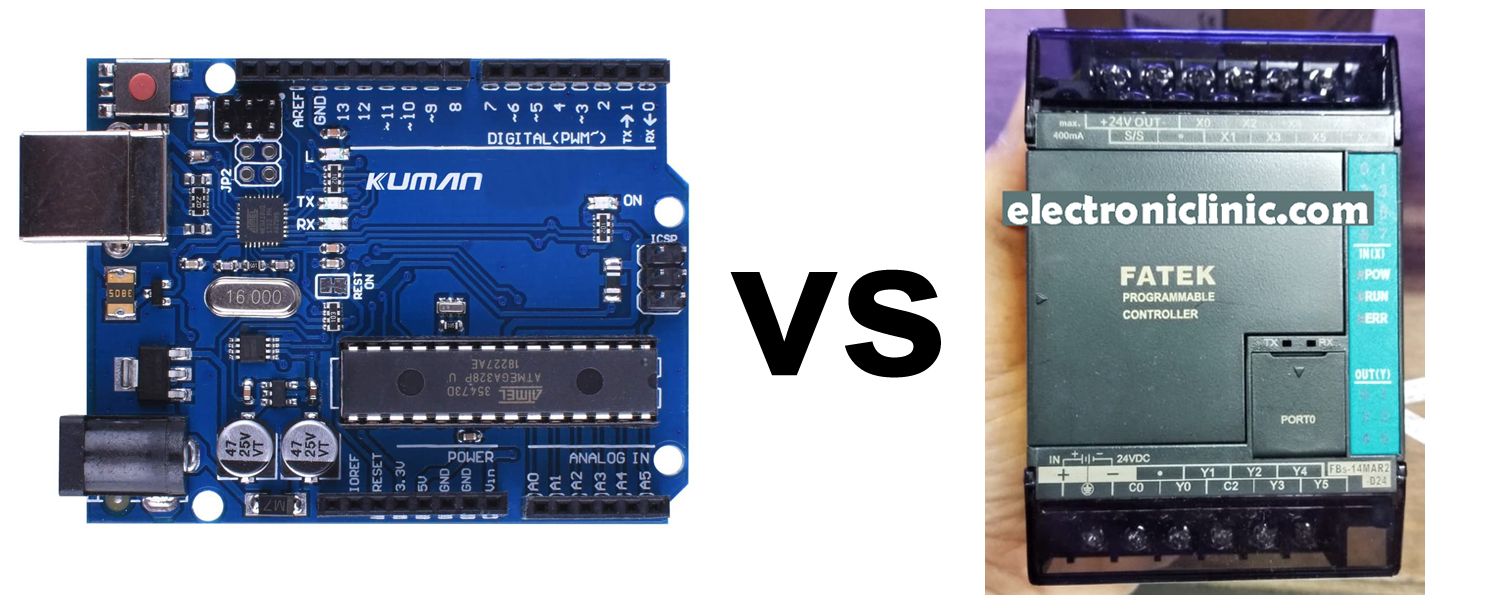

So, you're wondering if Arduino ventures into the world of Programmable Logic Controllers (PLCs)? It's a valid question! After all, both are microcontroller-based systems that allow us to automate processes. But think of it like asking if a scooter can replace a truck. Both provide transportation, but they serve different purposes and excel in different areas. An Arduino, at its heart, is a flexible, open-source microcontroller platform. A PLC, on the other hand, is a ruggedized, specialized computer designed for industrial control.

When we say "Does Arduino use PLC?" what we're really asking is: do they work together, and can one fully replace the other? The short answer is: they can work together, but one doesn't usually replace the other entirely. They're better suited to different tasks. Arduino shines in prototyping, hobbyist projects, and smaller, less critical applications. PLCs are the workhorses of heavy industry, controlling everything from manufacturing lines to power plants.

Think of it this way: Arduino is like a Swiss Army knife versatile and handy for a variety of tasks. A PLC is more like a specialized power tool incredibly powerful and reliable, but designed for a specific kind of work. You wouldn't try to build a house with just a Swiss Army knife, would you? (Well, you could, but it wouldn't be pretty, or structurally sound!).

The key difference lies in their intended environments and the level of reliability required. Arduino boards are typically used in environments that aren't too harsh, and where a potential failure isn't catastrophic. PLCs, in contrast, are built to withstand extreme temperatures, vibrations, and electrical noise. They also have built-in redundancy and safety features to prevent accidents and downtime. They're made to be tough cookies, designed to keep the industrial gears turning no matter what!

Arduino Vs PLC, Technical Specs, Pinout, And Programming Examples

Bridging the Gap

2. Synergy in Automation

While Arduino might not replace a PLC in a heavy-duty industrial setting, there are definitely scenarios where they can work together beautifully. Imagine a smart home system where an Arduino controls the lighting and temperature based on sensor data, and then communicates with a PLC that manages the overall energy consumption of the house. This kind of hybrid setup leverages the strengths of both platforms.

Another common application is data logging and monitoring. Arduino can be used to collect data from various sensors and send it to a PLC for further analysis and control. This is especially useful in situations where the sensors are located in remote or difficult-to-reach areas. Think of environmental monitoring in a factory — an Arduino could be placed near a specific machine to monitor its temperature and vibrations, sending the data back to the PLC for predictive maintenance.

Consider also the scenario of retrofitting older industrial equipment. Replacing an entire PLC system can be incredibly expensive and time-consuming. In some cases, it might be more cost-effective to use an Arduino to add new functionality to an existing PLC setup. For example, an Arduino could be used to implement a new communication protocol or to add a web interface for remote monitoring and control. It's like giving an old dog (the PLC) some new tricks!

Essentially, Arduino can act as a smart "helper" to the PLC, handling tasks that the PLC isn't ideally suited for. This allows you to create a more flexible and cost-effective automation system. Just remember to carefully consider the environmental conditions and safety requirements when integrating Arduino into an industrial environment.

The Nitty-Gritty

3. Diving Deeper into the Distinctions

Beyond the environmental resilience, there are significant technical differences between Arduino and PLCs. PLCs are designed for deterministic operation, meaning that their response time is predictable and consistent. This is crucial for safety-critical applications where timing is essential. Arduino, on the other hand, is not deterministic. Its response time can vary depending on the complexity of the code and the load on the microcontroller. This isn't a problem for many hobbyist projects, but it can be a major issue in industrial control.

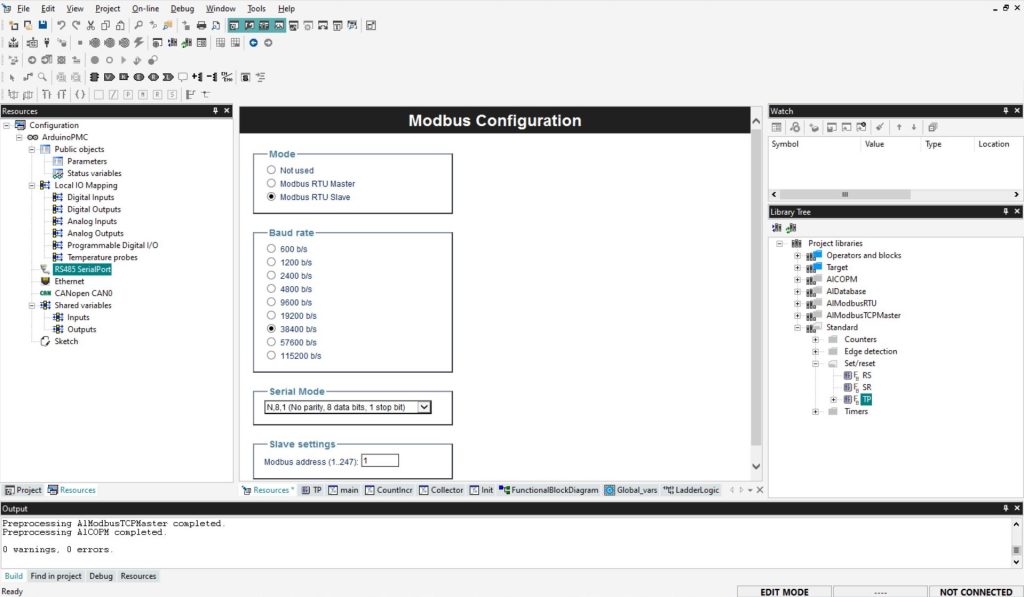

Programming PLCs typically involves using specialized languages like Ladder Logic, Function Block Diagram, or Structured Text. These languages are designed to be easy to understand and use by industrial technicians. Arduino, in contrast, is programmed using C++ (or a simplified version of it). While C++ is a powerful language, it can be more challenging to learn and use than PLC programming languages. So, the learning curve is different depending on your background and the task at hand.

Another key difference is in the input/output (I/O) capabilities. PLCs have a wide range of I/O modules that can be used to connect to various sensors, actuators, and other devices. These I/O modules are typically designed to be robust and reliable, and they often include built-in protection circuits to prevent damage from electrical surges or other hazards. Arduino also has I/O pins, but they are not as robust or versatile as those found on PLCs. This limits the types of devices that can be connected to an Arduino and increases the risk of damage to the board.

Finally, PLCs typically have built-in communication interfaces such as Ethernet, serial, and Modbus. These interfaces allow them to communicate with other PLCs, SCADA systems, and other industrial devices. Arduino can also be connected to networks, but it usually requires additional hardware such as an Ethernet shield or a Wi-Fi module. The choice of communication protocol will depend on the specific application and the devices that need to be connected.

Arduino PLC IDE Aims At Programmers Electronics Weekly

Arduino as a PLC? Exploring the Possibilities (and Limitations)

4. Pushing the Boundaries, Respecting the Limits

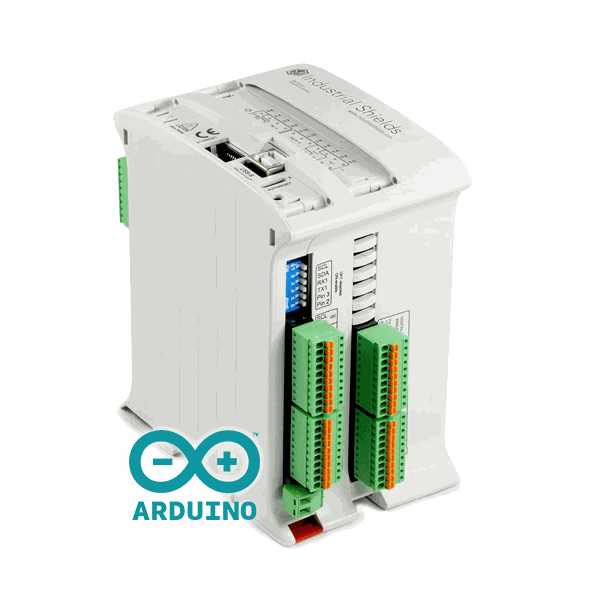

Can Arduino be used as a PLC? Technically, yes, to some extent. There are even Arduino-based PLC kits available. However, it's crucial to understand the limitations. These "Arduino PLCs" are generally suitable for small-scale, non-critical applications. Think of controlling a small greenhouse, or automating a simple machine. They're a good option for learning about PLC concepts without the investment of a full-fledged industrial PLC system.

The biggest challenge in using Arduino as a PLC is reliability. Arduino boards are not designed to withstand the harsh conditions found in industrial environments. They are also more susceptible to electrical noise and other interference. This means that they are more likely to fail, which can lead to downtime and potential safety hazards. This is a risk that must be weighed against the cost savings of using Arduino.

Software libraries like "Arduino PLC IDE" aim to make Arduino programming more PLC-like, allowing users to program using ladder logic. These tools are helpful but still don't overcome the hardware limitations. You're essentially putting a different operating system (ladder logic interpreter) on a hardware platform not explicitly designed for it.

Therefore, while Arduino can mimic some PLC functionalities, it's not a direct replacement for industrial applications demanding high reliability and deterministic operation. Think of it as a "PLC-lite" option, suitable for experimentation and small-scale projects, but not for controlling critical infrastructure or heavy machinery. Know your limits, and you'll avoid a lot of headaches down the road!

What Is A PLC And How Does It Work?

Making the Right Choice

5. Weighing Your Options

Ultimately, the decision of whether to use Arduino, a PLC, or a combination of both depends on the specific application. Consider the following factors: environmental conditions (temperature, humidity, vibration), required reliability and uptime, complexity of the control system, budget, and available expertise. If the application requires high reliability and deterministic operation in a harsh environment, then a PLC is the clear choice. If the application is small-scale and non-critical, and the budget is tight, then Arduino may be a viable option. And if you need a flexible and cost-effective automation system, a hybrid approach may be the best solution.

Don't underestimate the importance of safety. Industrial control systems can be dangerous if they are not designed and implemented properly. If you are not familiar with industrial safety standards, then it is best to consult with a qualified engineer. Cutting corners on safety is never worth the risk. Better safe than sorry, especially when dealing with powerful machinery and automated processes.

Remember to factor in the long-term cost of ownership. While Arduino boards are relatively inexpensive, the cost of maintenance and repair can add up over time. PLCs are more expensive upfront, but they are typically more reliable and require less maintenance. Consider also the cost of training and support. PLCs are often supported by a network of experienced integrators and technicians, while Arduino is more of a DIY platform. You might save money on the initial purchase, but spend more time troubleshooting and fixing things yourself. Which, depending on your enjoyment of tinkering, could be a pro or a con!

In conclusion, there is no single right answer to the question of whether Arduino uses PLC. The best approach depends on the specific needs of the application. By carefully considering the factors outlined above, you can make an informed decision that will result in a safe, reliable, and cost-effective automation system. Good luck, and happy automating!