Who Else Wants Tips About What Is The Full Form Of Triac

TRIAC Unveiled

1. Decoding the Acronym

Ever stumbled upon the term TRIAC while tinkering with electronics and wondered what it actually means? You're not alone! It's one of those acronyms that gets thrown around, but its full form isn't always immediately obvious. So, let's demystify it right away: TRIAC stands for TRIode for Alternating Current. Pretty straightforward, right? It's essentially a type of semiconductor device designed to control the flow of alternating current.

Think of a TRIAC like a super-efficient on/off switch for AC power. Unlike a regular diode that only lets current flow in one direction, a TRIAC can conduct current in both directions, making it ideal for applications where you need to control AC loads, such as lights, motors, and heaters. It's a clever little component that has simplified countless electronic designs.

The beauty of the TRIAC lies in its ability to be triggered into conduction by either a positive or negative gate signal, regardless of the polarity of the voltage applied across its main terminals. This makes it incredibly versatile and well-suited for controlling AC power in a variety of applications. Forget complicated rectifier circuits and directional constraints the TRIAC handles AC with ease and elegance.

In essence, understanding the full form TRIode for Alternating Current gives you a crucial clue about the TRIAC's purpose: it's a three-terminal device designed to control AC power. Knowing this simple fact makes the device much less intimidating and much easier to understand. Now, let's delve a little deeper and explore where you might find these handy components at work.

TRIACs in Action

2. Practical Applications

Now that we know what TRIAC stands for, let's explore its real-world applications. These little devices are surprisingly common, silently working away in many of the appliances and gadgets we use every day. Ever dimmed a light? Chances are, a TRIAC was involved! They're frequently used in light dimmers to control the amount of power reaching the bulb, allowing you to adjust the brightness to your liking.

Another common application is in motor control. TRIACs can be used to regulate the speed of AC motors, such as those found in fans, power tools, and even some washing machines. By controlling the amount of AC voltage supplied to the motor, the TRIAC effectively controls its speed. This gives you precise control over the device's operation, whether you're delicately adjusting the fan speed on a hot summer day or dialing in the right setting on your power drill.

Heating control is another area where TRIACs shine. They're often used in appliances like electric heaters and ovens to control the amount of heat generated. By switching the AC power on and off rapidly, the TRIAC effectively regulates the average power delivered to the heating element, allowing you to maintain a precise temperature. This is especially important in applications where consistent temperature is critical, such as industrial processes and laboratory equipment.

Beyond these common examples, TRIACs also find their way into various industrial control systems, solid-state relays, and other applications where reliable AC power control is essential. They are a crucial part of countless systems that make our lives easier and more efficient. So, the next time you're adjusting a dimmer switch or using a power tool, remember the TRIAC the unsung hero working tirelessly behind the scenes.

Triac Construction, Working, And Uses Electronic Clinic

Digging Deeper

3. The Inner Workings

While knowing the full form of TRIAC is helpful, understanding how it actually works takes your knowledge to the next level. Don't worry, we'll keep it relatively simple. A TRIAC is essentially two silicon-controlled rectifiers (SCRs) connected in inverse parallel. What that means is, the SCRs are connected back-to-back, allowing current to flow in either direction. Its kind of like having two one-way streets that merge into a two-way highway.

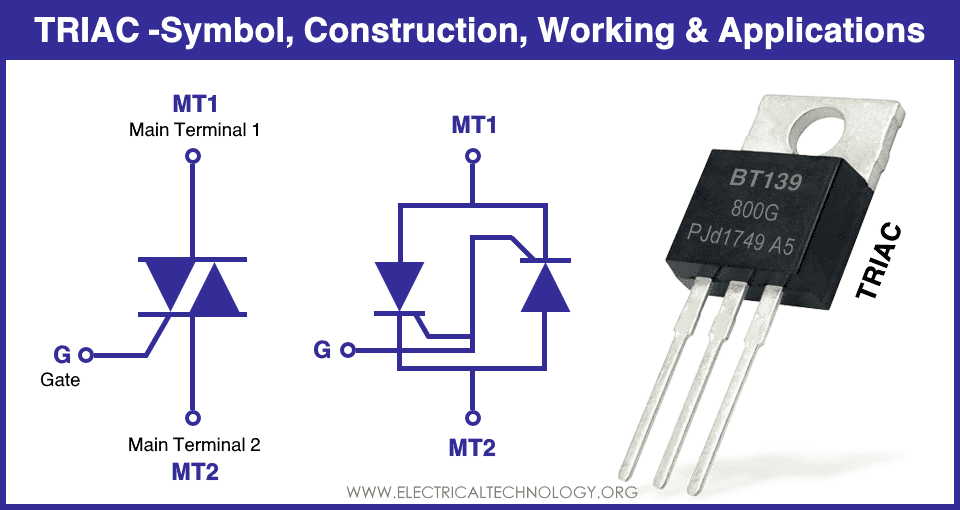

The TRIAC has three terminals: Main Terminal 1 (MT1), Main Terminal 2 (MT2), and Gate (G). The gate terminal is what you use to trigger the TRIAC into conduction. When a sufficient gate current is applied, the TRIAC switches "on," allowing current to flow between MT1 and MT2. The beauty of it is that this gate current can be either positive or negative, regardless of the polarity of the voltage between MT1 and MT2.

Once the TRIAC is triggered, it remains "on" as long as the current flowing through it exceeds a certain threshold called the holding current. If the current drops below the holding current, the TRIAC switches "off," blocking current flow. This is crucial for controlling AC power because AC voltage and current periodically cross zero. Each time the current crosses zero, the TRIAC naturally turns off, requiring a new gate signal to re-trigger it.

Think of it like a water faucet. The gate is like the handle, and the water flow is the AC current. Turning the handle (applying gate current) allows water to flow. Once the water is flowing, it continues to flow even if you release the handle a little (as long as the water pressure, or current, is strong enough). When the water pressure drops too low (current falls below the holding current), the faucet automatically shuts off, requiring you to turn the handle again.

TRIAC Full Form, Symbol, Working, VI Characteristic & Application

TRIAC vs. SCR

4. The Key Distinction

Since we mentioned SCRs (Silicon Controlled Rectifiers), it's natural to wonder about the difference between a TRIAC and an SCR. Both are semiconductor devices used to control electrical power, but the key distinction lies in their ability to handle alternating current. An SCR, like a regular diode, is a unidirectional device. It only allows current to flow in one direction. Think of it as a one-way valve.

A TRIAC, on the other hand, is a bidirectional device. It can conduct current in both directions, making it ideal for controlling AC power. As we discussed earlier, it's essentially two SCRs connected in inverse parallel, effectively creating a two-way valve. This ability to handle both positive and negative current makes the TRIAC much more versatile for AC applications.

Because SCRs are unidirectional, they are typically used in DC power control or in AC applications where only one direction of current flow is needed, such as in rectifiers or inverters. However, for applications like light dimming and motor speed control, where you need to control the entire AC waveform, the TRIAC is the more suitable choice.

In short, if you need to control DC power or only one direction of AC current, use an SCR. If you need to control the entire AC waveform, particularly in applications involving variable power, the TRIAC is your go-to component. The difference is subtle, but crucial for selecting the right device for the job.

Choosing the Right TRIAC

5. Selecting the Perfect Fit

Selecting the correct TRIAC for a specific application involves several considerations. First and foremost, you need to ensure that the TRIAC's voltage and current ratings are sufficient for the circuit it will be used in. Overlooking this can lead to component failure, potentially damaging the whole circuit. Voltage rating represents the maximum voltage the TRIAC can withstand without breaking down when it's in its 'off' state, while current rating states the amount of current the TRIAC can handle safely when it's switched 'on'

Another important factor is the gate trigger current. Different TRIACs require different amounts of gate current to switch on. You need to choose a TRIAC that can be reliably triggered by the available gate signal. This is because the gate current is the 'switch' to turn on the TRIAC. If the gate trigger current is too high, then the TRIAC simply wouldn't turn on because the system is not supplying enough current

The third consideration is the operating temperature range. TRIACs, like all semiconductor devices, have a limited operating temperature range. You need to select a TRIAC that can operate reliably within the expected temperature range of your application. Failure to do so can result in reduced performance or even complete failure. Think of it like how a car doesn't perform the same in the desert as it would in a cold climate.

Lastly, consider the specific requirements of your application. Are you controlling a highly inductive load, like a motor? If so, you might need a snubber circuit to protect the TRIAC from voltage spikes. Do you need a TRIAC with a specific package type for easy mounting? Answering these questions will help you narrow down your options and select the perfect TRIAC for your needs. Think of it like customizing a car - you would want to add components to make it fit your purpose.

Frequently Asked Questions (FAQs)

6. Answering Your Burning TRIAC Questions

Let's tackle some frequently asked questions about TRIACs:

Q: Can I use a TRIAC to control DC power?

A: Not directly. TRIACs are designed for AC power control. They need the alternating current to naturally turn off when the current crosses zero. You would need additional circuitry to use a TRIAC to switch a DC load.Q: What happens if I exceed the TRIAC's voltage or current rating?

A: Exceeding the voltage or current rating can damage or destroy the TRIAC. It's crucial to select a TRIAC with adequate ratings for your application.Q: Do TRIACs generate heat?

A: Yes, TRIACs generate heat, especially when switching high currents. You might need to use a heat sink to dissipate the heat and keep the TRIAC within its operating temperature range.Q: Are there different types of TRIACs?

A: Yes, there are different types of TRIACs, each optimized for specific applications. Some are designed for high-speed switching, while others are better suited for inductive loads. Always check the datasheet for the specific TRIAC you are using.