Build A Tips About How Are Wires Classified

5 Things You Should Know About Wires & Cables Firefly Electric

Understanding the World of Wires

1. Decoding Wire Classifications

Ever looked inside an appliance or the wall and seen a tangled mess of wires? It might seem chaotic, but there's actually a method to the madness! Wires aren't just wires; they're categorized in several ways to ensure safety, efficiency, and appropriate usage. Think of it like a library — everything has its place, even electricity's pathways!

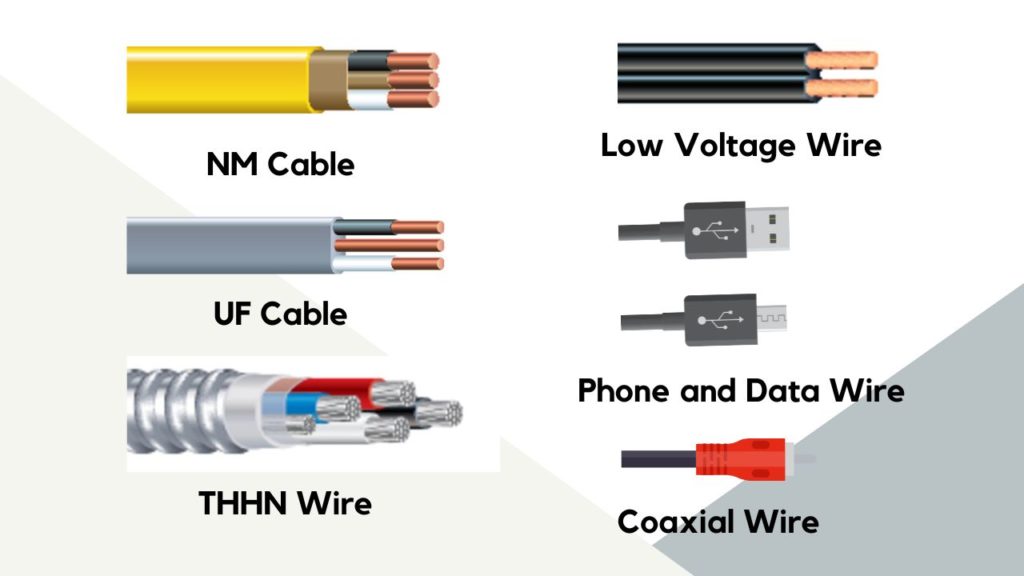

One primary way wires are classified is by their insulation type. This is the protective coating around the metallic conductor, and its crucial for preventing short circuits and electrical shocks. Different insulation materials are suitable for different environments and voltage levels. For example, THHN insulation is a common type used in dry locations, while THWN is designed to withstand moisture. Its like choosing the right raincoat for the weather — you wouldnt wear a light jacket in a downpour!

Another critical factor is the wire gauge, measured in American Wire Gauge (AWG). The lower the AWG number, the thicker the wire, and the more current it can safely carry. Imagine trying to drink a milkshake through a tiny straw — it's going to be difficult! Similarly, using a wire with too small of a gauge for the intended current can lead to overheating and potentially a fire hazard. So, always choose the right "straw" for the "milkshake" of electricity!

Furthermore, wires are often classified by their application. Some are designed for residential wiring, others for industrial use, and still others for specific devices like appliances or electronics. It's like having different types of roads for different vehicles — a bicycle lane isn't suitable for a semi-truck, and vice versa. Each type is optimized for its specific purpose, ensuring safety and reliable performance.

Types Of Electrical Wires The Family Handyman

Delving Deeper

2. More Than Meets the Eye

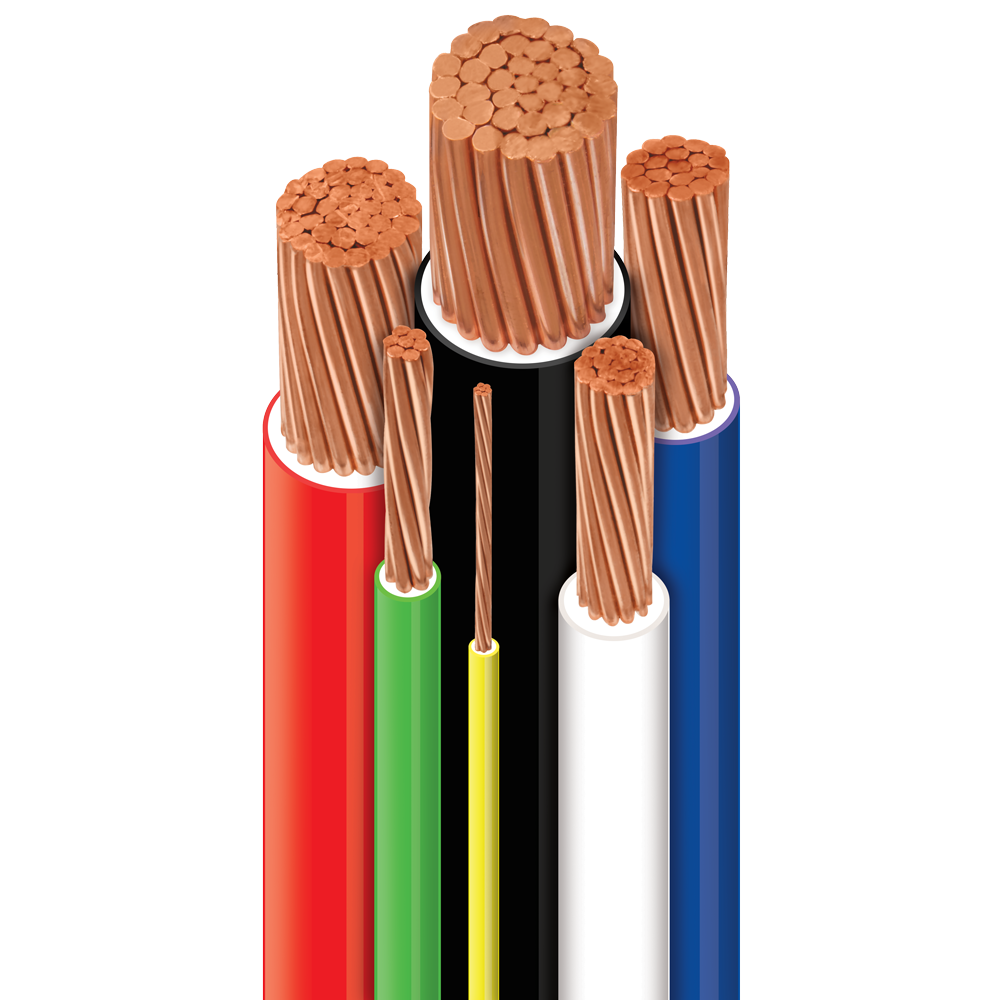

Beyond the basics, wire classifications get even more specific. You'll find distinctions based on the number of strands making up the conductor. Solid wires consist of a single, solid strand of metal, making them ideal for situations where rigidity and ease of termination are important. Stranded wires, on the other hand, are composed of multiple thin strands twisted together, offering greater flexibility and resistance to breakage from bending or vibration. It's like choosing between a sturdy oak beam (solid wire) and a flexible rope (stranded wire) depending on your needs.

Then theres the question of material. While copper is the most common conductor due to its excellent conductivity, aluminum is sometimes used as well, especially in overhead power lines, due to its lighter weight. It's like choosing between gold and silver jewelry — both are precious metals, but they have different properties and uses.

The National Electrical Code (NEC) plays a crucial role in classifying wires and setting standards for their safe and proper installation. It's like the rulebook for electrical installations, ensuring that everything is done according to best practices and safety regulations. Ignoring the NEC is like driving without a license — risky and potentially dangerous!

Finally, consider the environment where the wire will be used. Will it be exposed to moisture, extreme temperatures, or corrosive chemicals? Special types of wires are designed to withstand these harsh conditions. Its like choosing the right clothing for different weather conditions — you wouldnt wear a swimsuit in the snow!

Wire And Cable Are Used For Transmitting Power From One Place To

Color Codes

3. Cracking the Code

Ever notice how wires are often different colors? This isn't just for aesthetics; it's a crucial safety feature! Color coding helps electricians quickly identify the purpose of each wire, reducing the risk of wiring errors and electrical accidents. It's like having a map for an electrical circuit, making it easier to navigate and troubleshoot.

In North America, the standard color codes are typically as follows: black for hot (live) wires, white for neutral wires, and green (or bare copper) for ground wires. However, these color codes can vary depending on the specific application and local regulations. Always double-check the applicable codes before working with electrical wiring. It's like learning the local customs when traveling to a new country — you want to avoid any misunderstandings!

Sometimes, you might encounter other colors, such as red or blue, which are often used for switch legs or control wires in more complex circuits. These colors help distinguish these wires from the main power supply. Its like having different colored pens to highlight important information in a document — it makes things easier to understand at a glance.

Remember, color coding is a valuable tool, but it's not foolproof. Always use a multimeter to verify the voltage and function of a wire before working on it. Its like trusting your GPS, but still double-checking the road signs to make sure youre on the right track.

:max_bytes(150000):strip_icc()/electrical-cable-cutting-stripping-preparation-669377248-5abc41d7a18d9e0037d90043.jpg)

The Importance of Proper Wire Selection

4. Getting it Right

Selecting the right type of wire for a specific application is absolutely critical for safety and reliability. Using the wrong wire can lead to a range of problems, from minor inconveniences like flickering lights to serious hazards like electrical fires. It's like building a house on a weak foundation — eventually, it's going to collapse!

Overloading a wire, by exceeding its current carrying capacity, can cause it to overheat and melt the insulation. This can create a short circuit, leading to a fire. Imagine trying to force too much water through a garden hose — it's going to burst!

Using the wrong type of insulation can also be problematic. For example, using a wire with insulation that's not rated for wet locations in a damp environment can lead to corrosion and eventual failure. It's like wearing cotton clothing in the rain — you're going to get soaked and uncomfortable!

Always consult the National Electrical Code (NEC) and local regulations to ensure that you're using the correct type of wire for your application. When in doubt, consult with a qualified electrician. It's always better to be safe than sorry when it comes to electricity!

Frequently Asked Questions (FAQs)

5. Your Burning Questions Answered

Here are some frequently asked questions about wire classifications to help you further understand this important topic:

Q: What's the difference between THHN and THWN wire?

A: THHN and THWN are both types of building wire commonly used in residential and commercial applications. THHN stands for Thermoplastic High Heat-resistant Nylon, indicating it's heat-resistant and has a nylon coating. THWN stands for Thermoplastic Heat- and Water-resistant Nylon, meaning it's also water-resistant, making it suitable for damp locations. Think of THWN as the all-weather version of THHN.

Q: How do I determine the correct wire gauge for a circuit?

A: The correct wire gauge depends on the amperage of the circuit and the length of the wire run. Consult the National Electrical Code (NEC) or a qualified electrician to determine the appropriate gauge for your specific application. There are charts and formulas that help determine this based on the load and distance. It's like figuring out how much weight a bridge can hold — you need to know the load and the span.

Q: Can I use aluminum wire instead of copper wire?

A: Aluminum wire can be used in some applications, but it requires special considerations. Aluminum has a higher resistance than copper, so it needs to be a larger gauge to carry the same amount of current. Also, aluminum expands and contracts more than copper, which can loosen connections over time. Special connectors and installation techniques are required to prevent these problems. Think of it like using a different type of fuel in your car — you need to make sure the engine is compatible!

Q: What does "stranded" versus "solid" core mean?

A: Solid core wires are just that — a single, solid piece of metal. Stranded wire is made up of many smaller strands of metal twisted together. Stranded wire is much more flexible and resistant to breaking when bent repeatedly, so it's used in applications where movement is expected. Solid core is typically used in permanent installations where the wire will be relatively stationary, such as inside walls.

Q: Where can I learn more about electrical wiring and safety?

A: There are many resources available, including the National Electrical Code (NEC), online tutorials, and courses offered by local community colleges and trade schools. Always prioritize safety and consult with a qualified electrician if you have any doubts. It's like learning to drive — take a class and practice with a qualified instructor!